Calculating the Cost of Laser Cutting with Bending for Multiple Parts in CUTL

- Boris

- Oct 30

- 4 min read

Updated: 6 days ago

Previously, we described the method for calculating the cost of part cutting and its implementation in CUTL using a DXF drawing file.

In this article, we will look at a more complex and realistic scenario — especially relevant for those working with metal parts manufacturing.

Typical Metal Fabrication Workshop Setup

A metal laser cutting department usually includes more than just laser machines. A traditional workshop often consists of:

Laser cutting section (one or several laser machines)

Bending section (various bending presses)

Since many customer orders require bending of the cut parts, additional equipment is often necessary.

Optionally, depending on available resources and space, there may also be:

Painting section

Welding section

Manual finishing area (thread cutting, grinding, assembly, etc.)

Accordingly, when calculating part cost, it’s important to consider more than just laser cutting.

Moreover, customer requests are rarely for single parts. Quite often, orders look like this:

It’s ideal when such an email includes both PDF and DXF files — this greatly speeds up the process.

If the customer doesn’t have DXF files, you’ll have to prepare them yourself.

Project Concept in CUTL

To handle such orders, CUTL introduces the concept of a “Project.”

Create a new project and fill in its Name. The other fields are optional — you may specify the customer and any relevant information in the Description field. Then click “Save.”

If you need VAT to be displayed in the quote and want your company details to appear in the commercial offer, you can enter your company data and VAT rate in “Dictionaries → Organizations.”

Once the project is saved, you can upload all necessary drawing files, which will be processed automatically:

Depending on the number of parts and file complexity, processing may take several minutes per file. After completion, all parts appear in the “Parts” section of the project:

Double-click on a part to open the part cost calculation window.

Part Cost Calculation

Just like in Quick Calculation, you only need to select the material and cutting mode to instantly get the part price.

However, there are additional options: in the “Operations” tab (top right), you can add post-cutting operations that will be performed on the part.

To use this, make sure you’ve previously filled in the list of possible operations and their fixed prices.

For example, let’s add a Bending operation:

After adding it, open the “Operations” tab in the part calculation and specify the required bends.

Then, in the main “Calculation” tab, you can see the results:

Here you’ll see two prices:

Price per piece — cost for material and cutting only.

Total price — cost including all additional operations (in this example, one bend at 150 usd each, totaling +150 usd).

After entering the required quantity of parts, you’ll get the total amount. (4 items = 600.4 usd)

If necessary, you can manually adjust the calculated price.

When the new value exceeds the calculated one, a green mark appears; if it’s lower — a red mark appears.

Thus, we have calculated the cost of a part including bend:

Processing the Next Parts

Now we can proceed to the next part — select material and cutting mode.

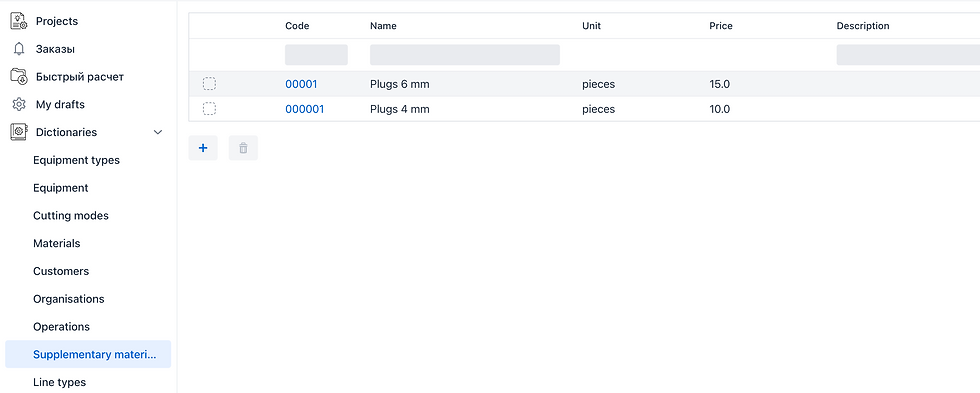

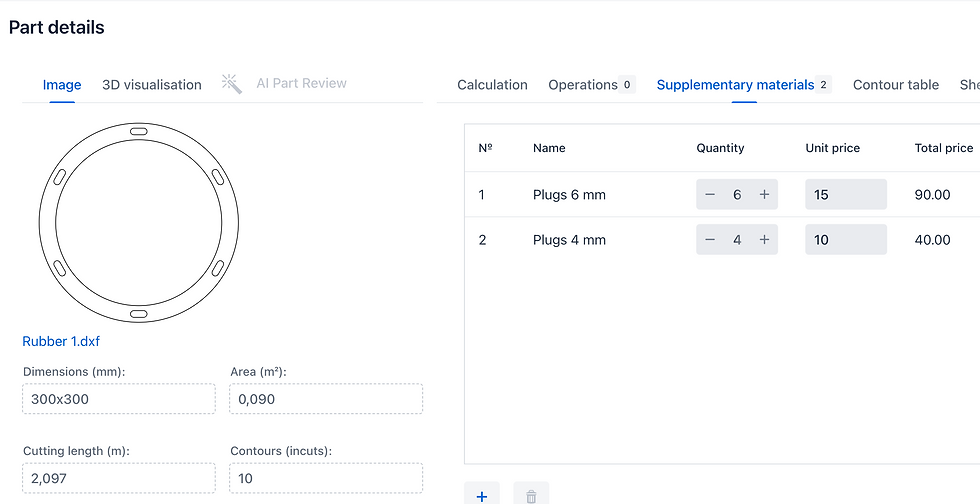

Suppose, according to the design documentation, this plate includes plugs. You can add supplementary materials using Dictionaries -> Supplementary materials view

And after it also can be factored into the plate’s cost using the “Additional Materials” tab (top right).

The Calculation tab will then show both the cutting cost and the part price including the plugs.

Click “Save” and move to the next part.

Let’s assume that for the next part, holes shouldn’t be laser-cut — they will be drilled after bending according to the drawings.

In that case, we need to:

Include bending

Disable laser cutting of holes

Add drilling operation

To include bending and drilling, go to “Operations” and add them.

Of course, the drilling operation must be pre-defined in the list of available operations.

You can set its price directly in the operations table.

To disable hole cutting, open the “Contours Table.”

Here you can see all drawing contours and exclude specific ones from cutting.

Excluded contours are highlighted in red on the drawing. You’ll also notice that the cutting length decreases accordingly.

As a result, you get a calculation that includes bending and drilling, while excluding holes from laser cutting.

Generating Results

Now the entire project is calculated — all part prices are ready, quantities are set, and you can view the total project cost and total material consumption.

You can export the calculation result as a PDF:

The PDF file first shows a project summary table:

Columns M and O indicate whether Additional Materials or Operations were included in the calculation.

Then, each page provides a detailed part breakdown.

If a part price was manually changed, this is also displayed in the report.

Sharing and Collaboration

The project results can be reviewed online by the customer or your colleagues — simply send them a public link to the project.

For example: [public project link].

This link allows others to see the project result without detailed breakdowns.

Each part has two comments:

An internal comment,

A customer comment, which is displayed in the public view.

The public page provides a simplified part description for easier review.

Commercial Offer in PDF

You can also generate a commercial proposal in PDF format.

It can either be downloaded or sent directly by email to the customer.

The PDF header automatically includes your organization name, phone, and email, which can be pre-filled under Dictionaries → Organizations.

When sending by email, you can enable the “Send copy to me” checkbox — this way, the message will be sent both to the customer and to your registered email address for tracking.

Summary

With CUTL, you can process a customer request in just minutes, taking into account not only laser cutting, but also bending, drilling, materials, and other additional operations and costs — all in one streamlined calculation.

Comments